HACCP Plan Form 2010-2026 free printable template

Show details

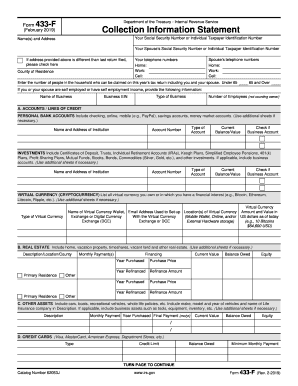

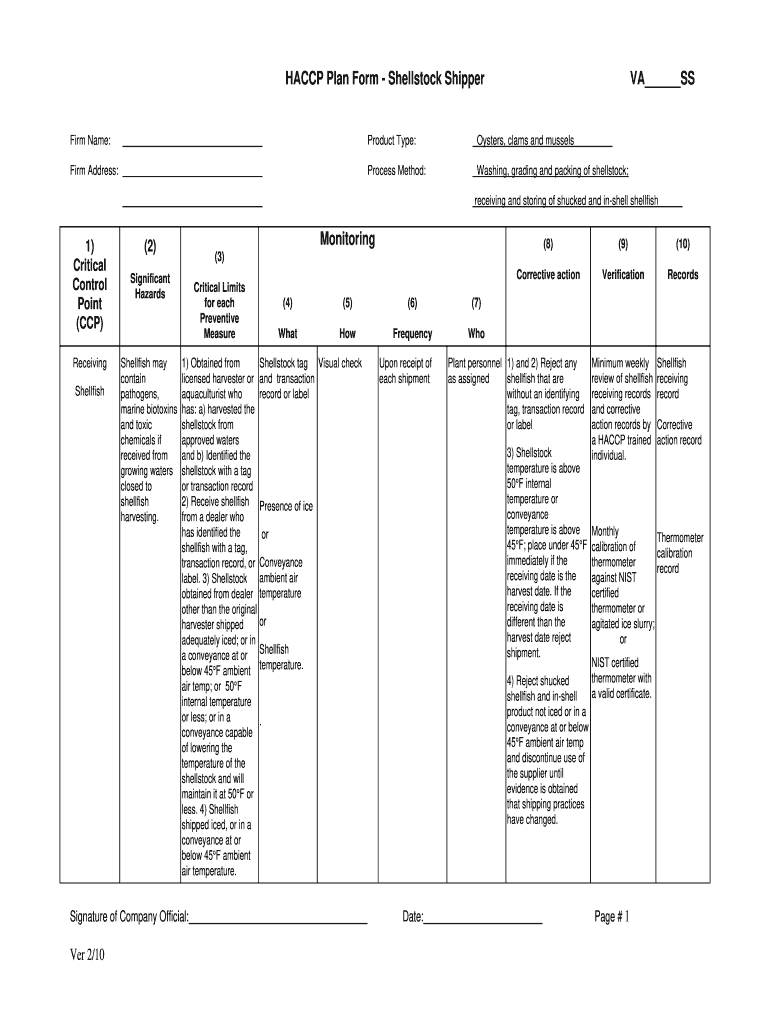

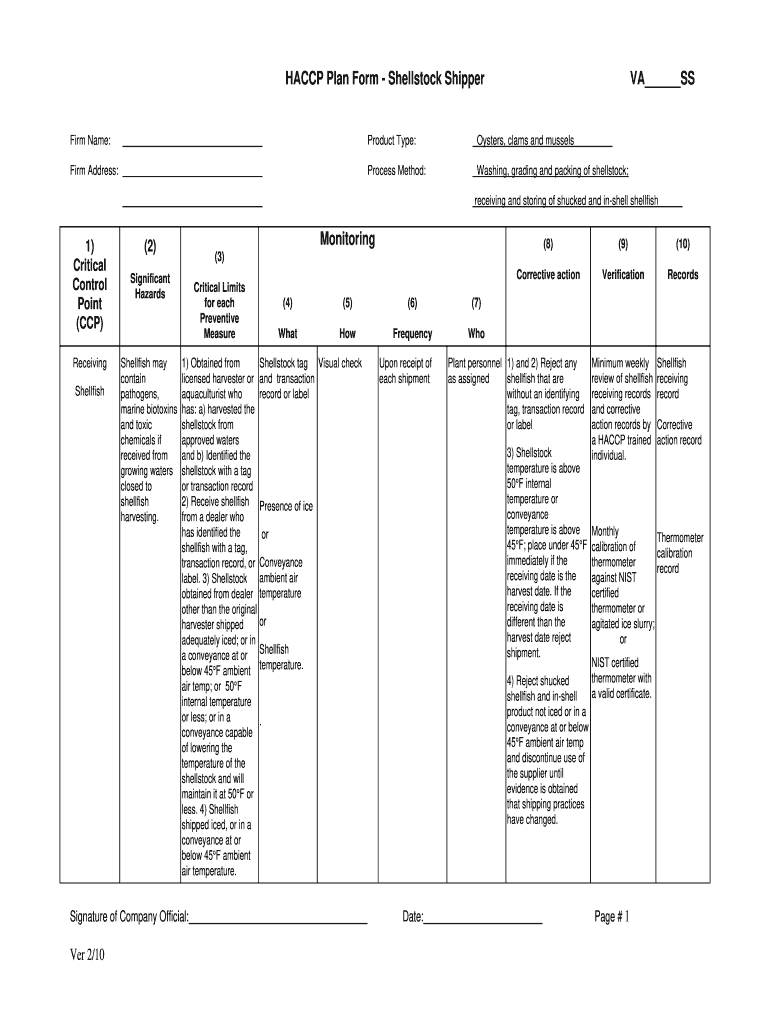

HACCP Plan Form She'll stock Shipper VA SS Firm Name: Product Type: Oysters, clams and mussels Firm Address: Process Method: Washing, grading and packing of shell stock; receiving and storing of shucked

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign haccp form ss

Edit your haccp plan form form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your sample haccp plan for restaurant form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit haccp shipper fillable online

Use the instructions below to start using our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit haccp plan for restaurant form. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out conveyance haccp search form

How to fill out HACCP Plan Form

01

Gather necessary documentation and food safety guidelines.

02

Identify the food products that will be covered by the HACCP plan.

03

Assemble a HACCP team with diverse expertise.

04

Conduct a hazard analysis to identify potential food safety hazards.

05

Determine Critical Control Points (CCPs) where hazards can be prevented or controlled.

06

Establish critical limits for each CCP (e.g., temperature, time).

07

Develop monitoring procedures for each CCP to ensure compliance.

08

Create corrective actions for when monitoring indicates a deviation from critical limits.

09

Establish verification procedures to confirm that the HACCP plan is working effectively.

10

Develop documentation and record-keeping requirements to track compliance.

Who needs HACCP Plan Form?

01

Food manufacturers and processors.

02

Restaurants and food service operations.

03

Retail food establishments.

04

Catering businesses.

05

Food distributors and suppliers.

06

Any facility that handles food products.

Fill

haccp plan template maryland

: Try Risk Free

People Also Ask about example of haccp plan for restaurant

When did FDA mandated HACCP rules for all seafood?

On December 18, 1995 (60 FR 65096), FDA published final regulations (21 CFR part 123) that require processors of fish and fishery products to develop and implement HACCP systems for their operations. Those regulations became effective on December 18,1997.

What is seafood HACCP certification?

This training helps fishermen, dealers, processors, regulatory personnel and others identify and evaluate the critical points during handling and production of seafood and seafood products in order to set up control measures – or HACCP plans – that help ensure safe seafood.

What are the 7 examples of HACCP?

Seven basic principles are employed in the development of HACCP plans that meet the stated goal. These principles include hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation.

Does seafood require HACCP?

A HACCP system is required to be implemented for all wholesale processors and distributors of seafood.

How do I fill out a HACCP plan?

Make an HACCP food plan identify any hazards that must be avoided, removed or reduced. identify the critical control points ( CCPs ) - the points when you need to prevent, remove or reduce a hazard in your work process. set limits for the CCPs. make sure you monitor the CCPs.

How do you write a HACCP plan example?

Below are the HACCP writing stages and ways how to make food HACCP plan examples: Identify and analyze all hazards. Establish critical control points (CCP) Set up critical limits. Build a monitoring procedure system for CCPs. Identify corrective actions. Verify the whole HACCP plan. Record-keeping and documentation.

Who is required to have a HACCP plan?

A specific Food Safety/HACCP plan is needed for each food and for each processing system employed by a food business because every food and every processing system/procedure poses different risks and requires different risk management practices.

Is HACCP mandatory for seafood?

The seafood industry mandates all seafood processors to have a HACCP plan and properly implement it throughout their operations.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send haccp shipper printable for eSignature?

When you're ready to share your sample haccp plan, you can swiftly email it to others and receive the eSigned document back. You may send your PDF through email, fax, text message, or USPS mail, or you can notarize it online. All of this may be done without ever leaving your account.

How do I edit plan shellstock in Chrome?

Download and install the pdfFiller Google Chrome Extension to your browser to edit, fill out, and eSign your shellfish f haccp, which you can open in the editor with a single click from a Google search page. Fillable documents may be executed from any internet-connected device without leaving Chrome.

How can I fill out haccp shellstock fillable on an iOS device?

Install the pdfFiller app on your iOS device to fill out papers. If you have a subscription to the service, create an account or log in to an existing one. After completing the registration process, upload your shellfish haccp plan. You may now use pdfFiller's advanced features, such as adding fillable fields and eSigning documents, and accessing them from any device, wherever you are.

What is HACCP Plan Form?

The HACCP Plan Form is a documented system that identifies, evaluates, and controls hazards that are significant for food safety. It outlines the critical control points (CCPs) and the procedures to ensure that food safety practices are consistently followed.

Who is required to file HACCP Plan Form?

Food processing establishments, particularly those involved in the manufacturing of meat, poultry, and seafood products, are required to file a HACCP Plan Form. It is mandated by regulatory agencies to ensure compliance with food safety regulations.

How to fill out HACCP Plan Form?

To fill out a HACCP Plan Form, follow these steps: 1) Identify the food product and its intended use, 2) List potential hazards associated with each step in the food production process, 3) Determine critical control points, 4) Establish critical limits for each CCP, 5) Identify monitoring procedures, 6) Describe corrective actions for deviations, 7) List verification procedures, and 8) Maintain record-keeping and documentation requirements.

What is the purpose of HACCP Plan Form?

The purpose of the HACCP Plan Form is to provide a structured approach to food safety by identifying potential hazards and implementing controls to reduce or eliminate risks. It ensures compliance with regulations and promotes the safe production of food.

What information must be reported on HACCP Plan Form?

The information that must be reported on the HACCP Plan Form includes the product description, process flow chart, identified hazards, critical control points, critical limits, monitoring procedures, corrective actions, verification processes, and maintenance of records related to food safety.

Fill out your HACCP Plan Form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Haccp Template Download is not the form you're looking for?Search for another form here.

Keywords relevant to haccp plan template excel

Related to how to write a haccp plan

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.